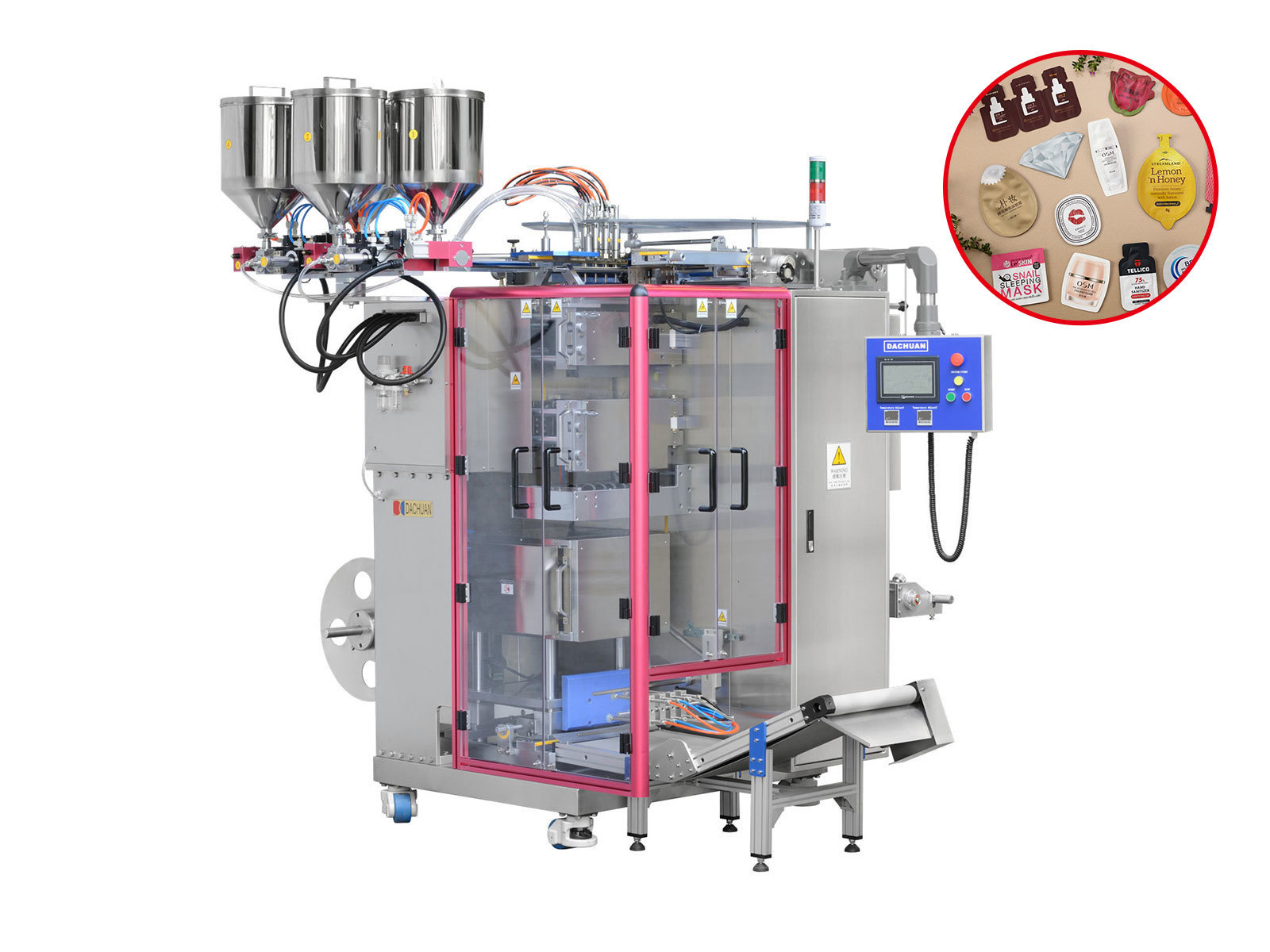

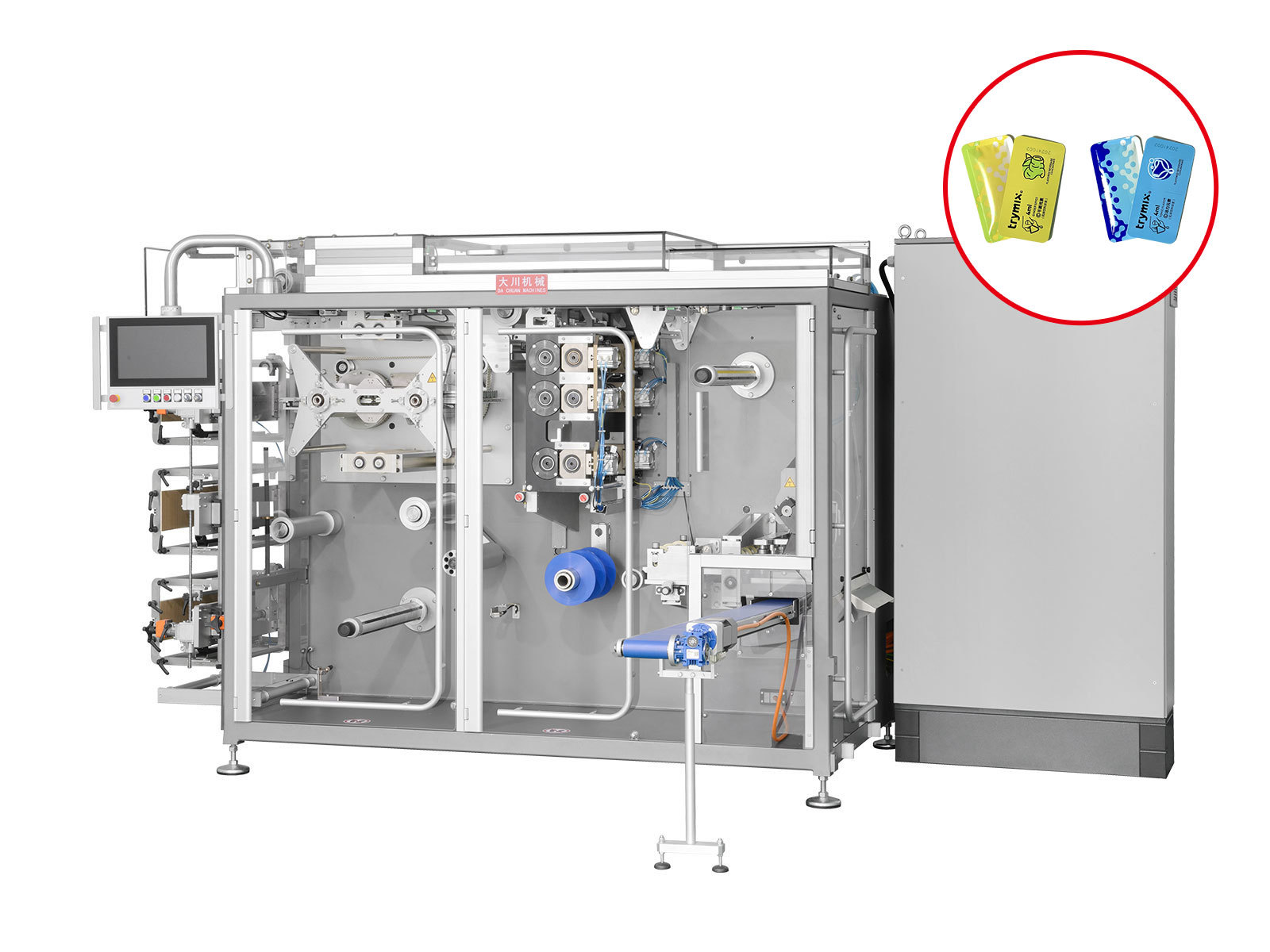

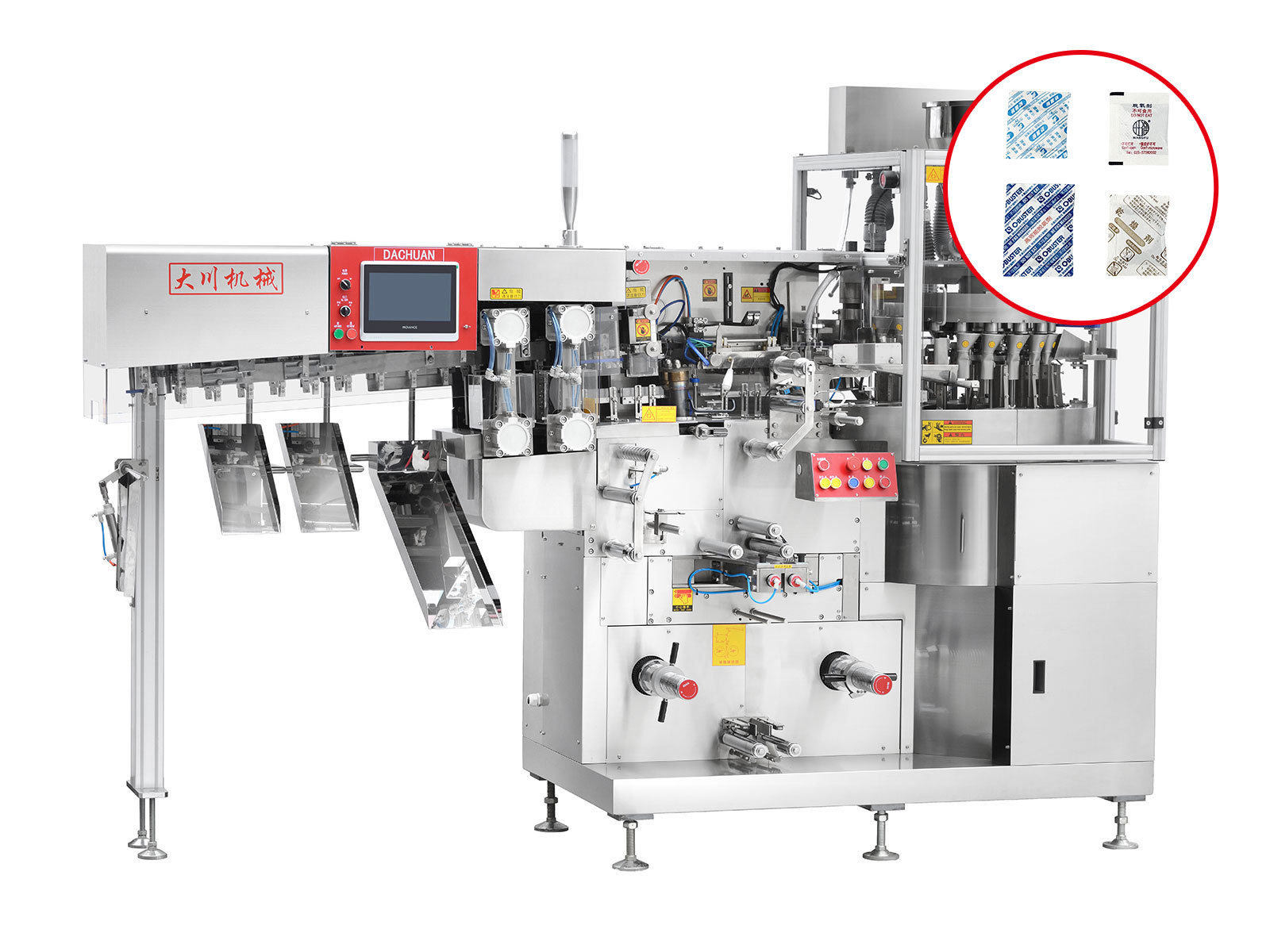

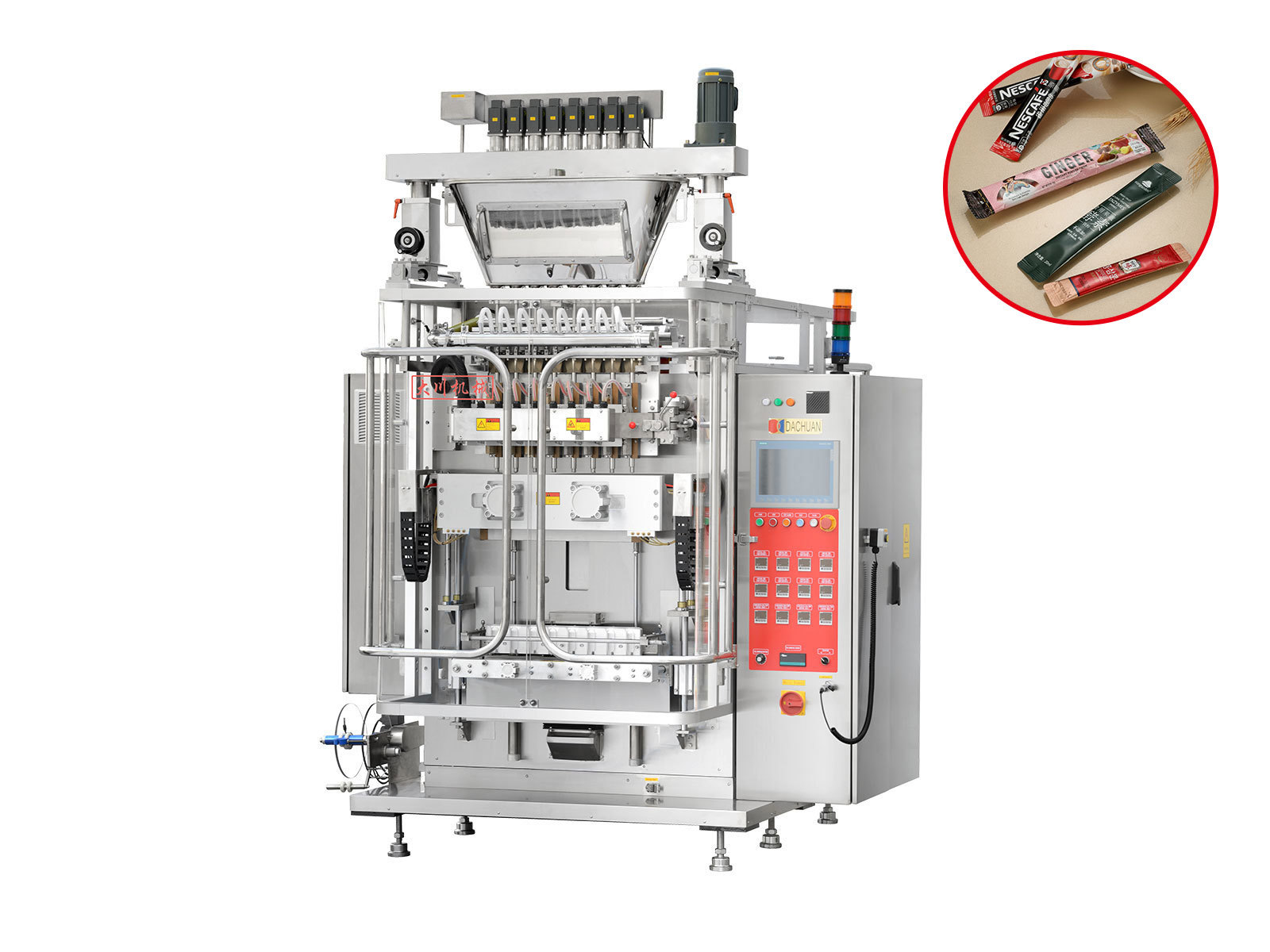

DC-860 Double-sided blister packaging machine

Category: Blister packaging equipment

Guangdong Province High-tech Enterprise, Fully Automatic High-speed High-performance Intelligent Packaging Machines Engineering Technology Research Center, specializing in the manufacture of packaging machines. Main products include: pillow packaging machine, fully automatic soft tube sealing machine, multi-row irregular machine, double-sided blister machine, single-sided blister machine, fully automatic lipstick filling equipment, capping machine, multi-row/single-row back sealing machine, fully automatic horizontal packaging machine, multi-row high-speed packaging machine, vertical small bag machine and other packaging equipment.

Product details

Mechanical Characteristics:

The DC-860 double-sided blister machine is mainly a filling machine for metering and packaging liquid and semi-viscous products. This product is designed to meet the needs of liquid and semi-viscous product packaging using plastic roll film. The production line is simple, safe, and can reduce product production costs. Modular design, simple structure, short design cycle, and fast product updates. Reasonable structure, reliable quality, stable operation, and long service life.

Suitable Packaging Materials:

Packaging materials can be single materials or composite materials, with wide applicability. PVC(PE), PET(PE), PVDC, and various other materials can be formed. Packaging material utilization is high, typically reaching over 95%, and even up to 99% in some cases.

| Equipment Technical Parameters | ||||||

| Machine Model | DC-860 | |||||

| Maximum Roll Film Diameter | 400mm (including core inner diameter 76mm) | |||||

| Production Specifications | (0.3~0.4) x 240 (maximum) mm | |||||

| Number of Fillings per Plate | 2-5 units/plate | |||||

| Filling Capacity | 1-20ml/unit | |||||

| Packaging Speed | 10-20 forming cycles/minute | |||||

| Single-sided Forming Depth | 2-10mm | |||||

| Double-sided Forming Depth | 10-20mm | |||||

Keyword: DC-860 Double-sided blister packaging machine

Previous: DC-688S High-speed Blister Packaging Machine

Next: No more!

DC-860 Double-sided blister packaging machine

The DC-860 double-sided blister packaging machine is mainly a filling machine for metering and packaging liquid and semi-viscous products. This product is designed to meet the needs of liquid and semi-viscous products packaged with plastic roll film. The production line is simple, safe, and can reduce product production costs. Modular design, simple structure, short design cycle, and fast product updates. Reasonable structure, reliable quality, stable operation, and long service life. Packaging materials can be single materials or composite materials, with wide applicability. Various materials such as PVC(PE), PET(PE), and PVDC can be formed. The utilization rate of packaging materials is high, usually reaching more than 95%, and some even reach 99%.

Related products

Product inquiry

Leave the information you want to consult, and we will contact you as soon as possible