About Us

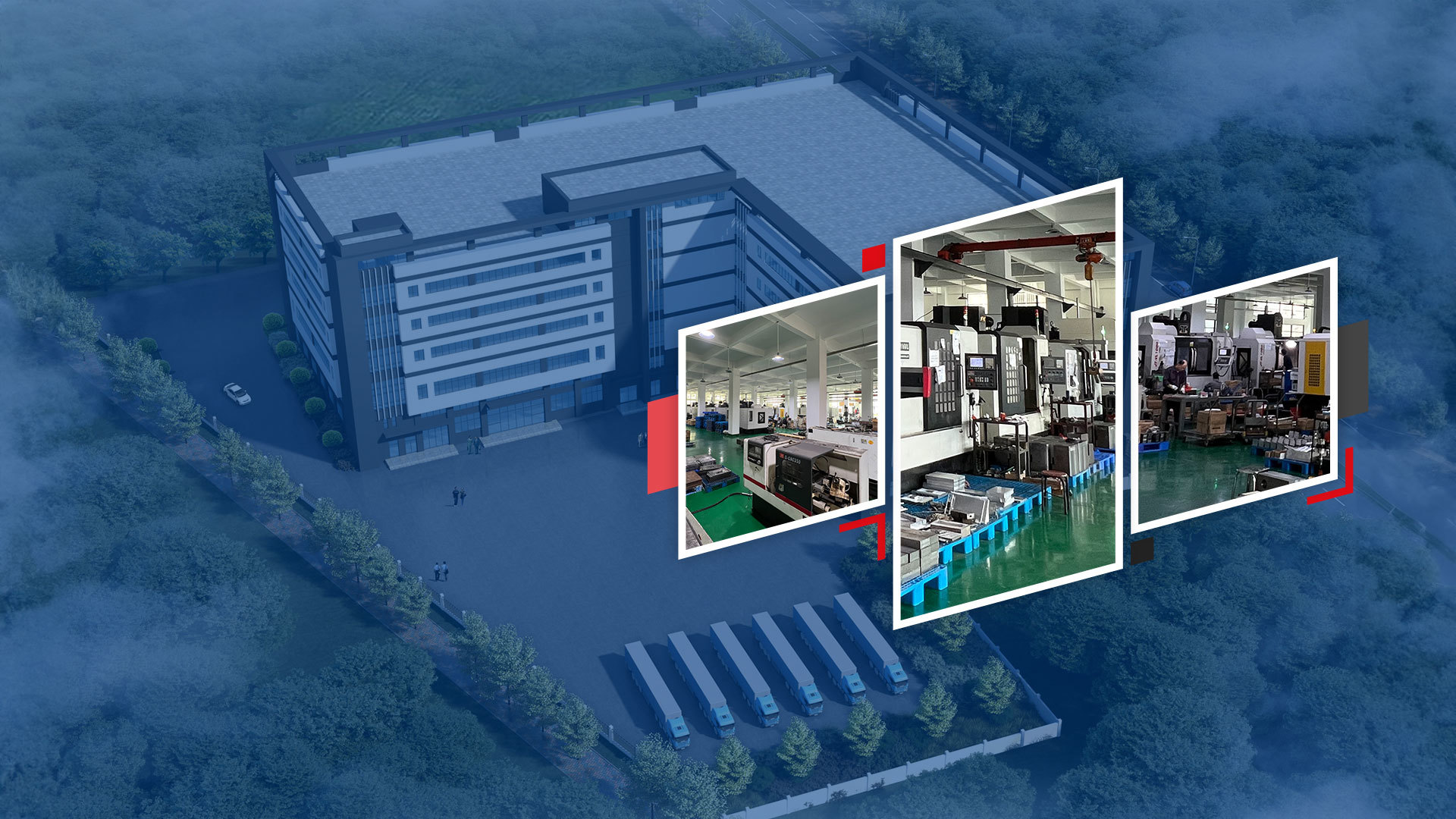

Shantou Dachuan Machines Co., Ltd.

Guangdong Province High-tech Enterprise, Fully Automatic High-speed High-performance Intelligent Packaging Machines Engineering Technology Research Center

Founded in

Number of employees

Patent

R&D engineer

Over 30 mature products

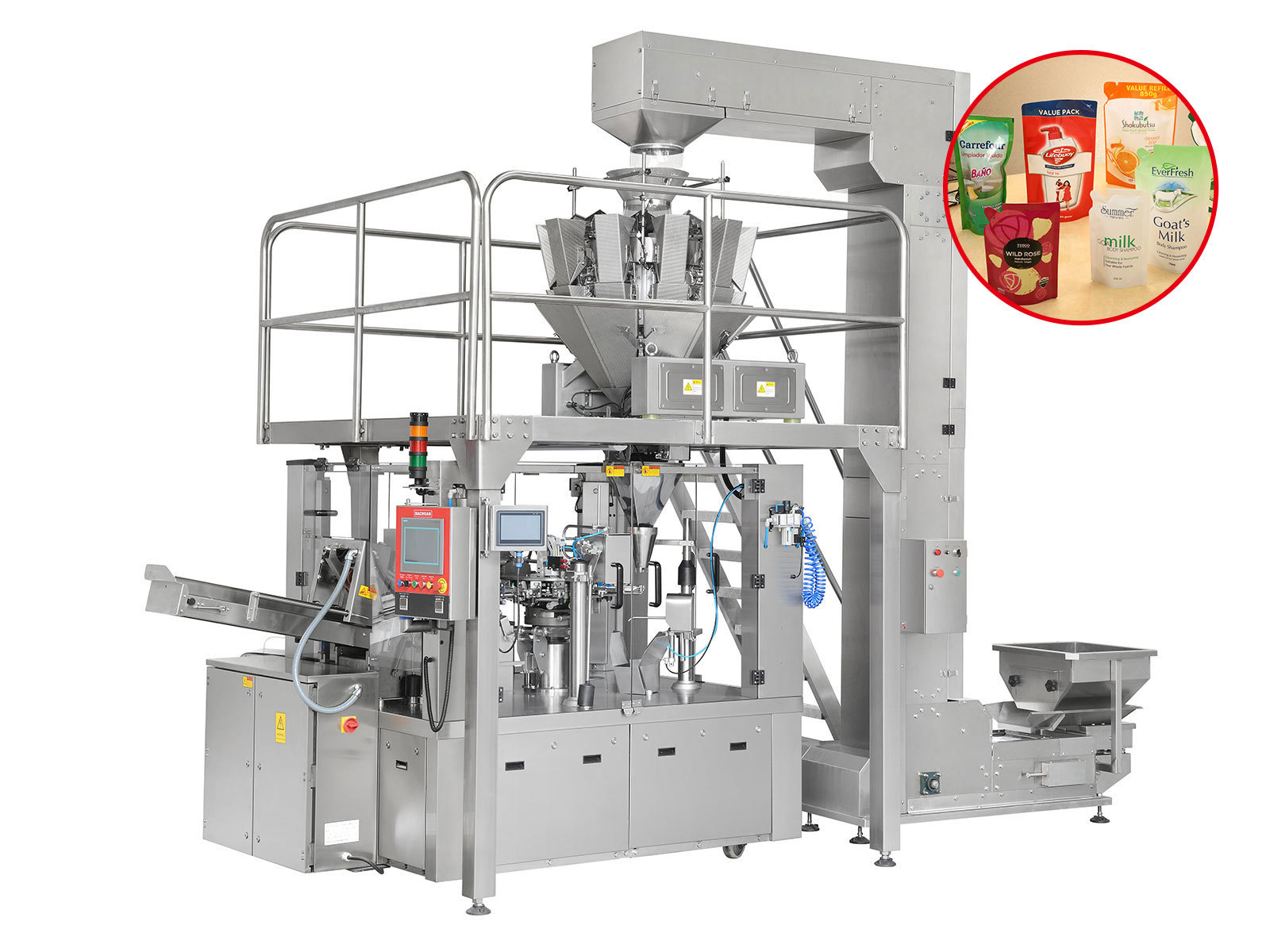

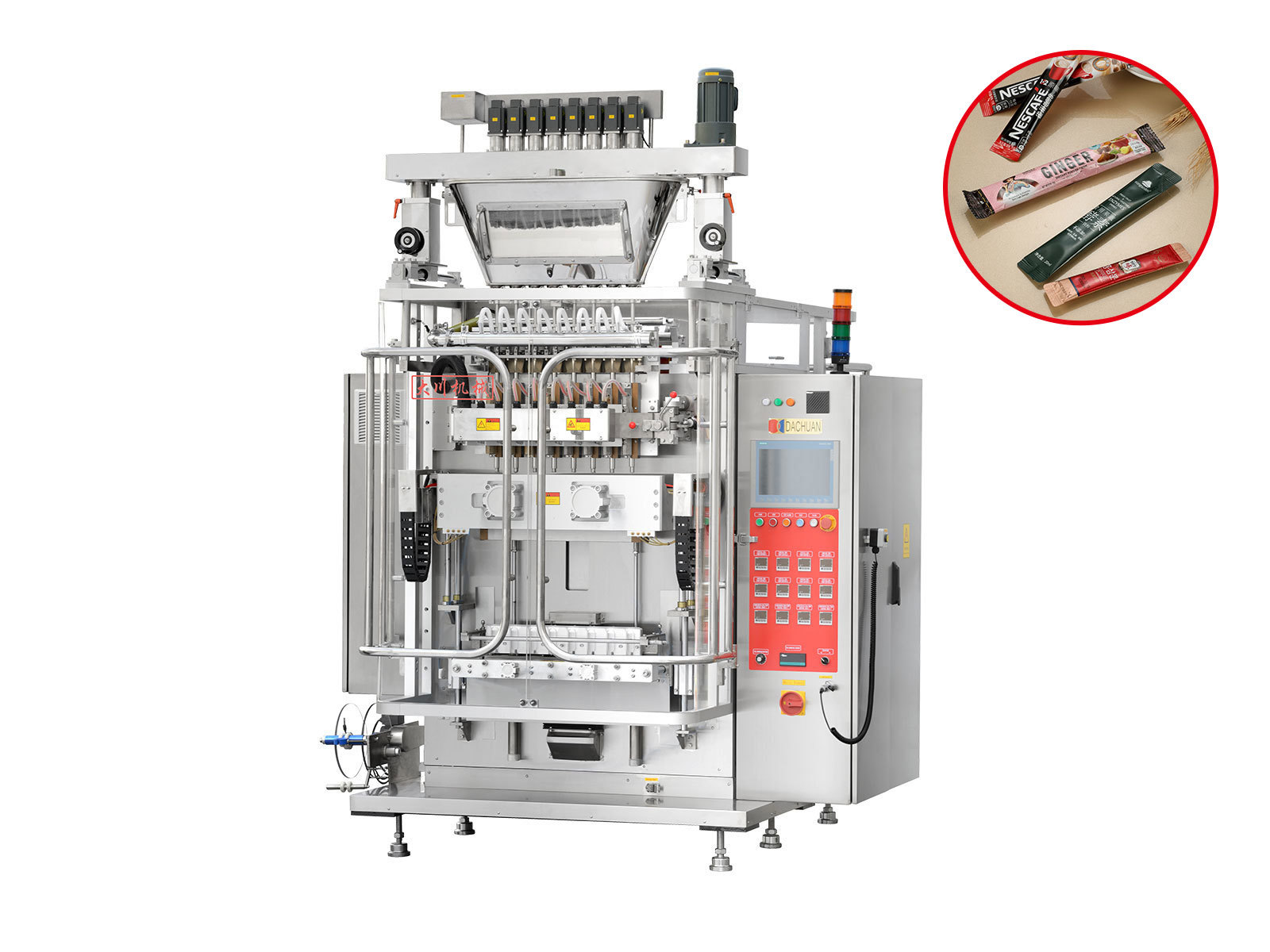

PRODUCTS

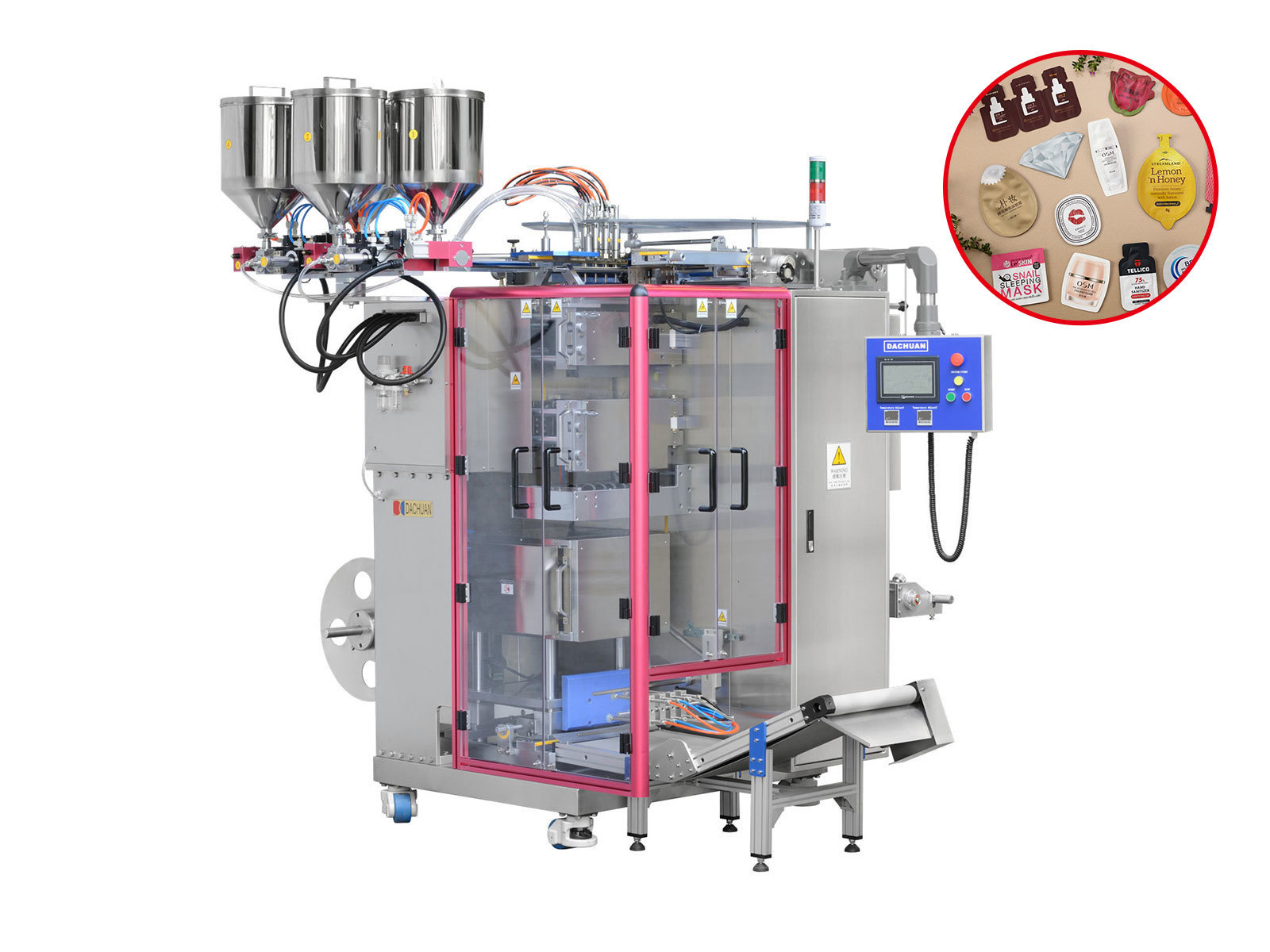

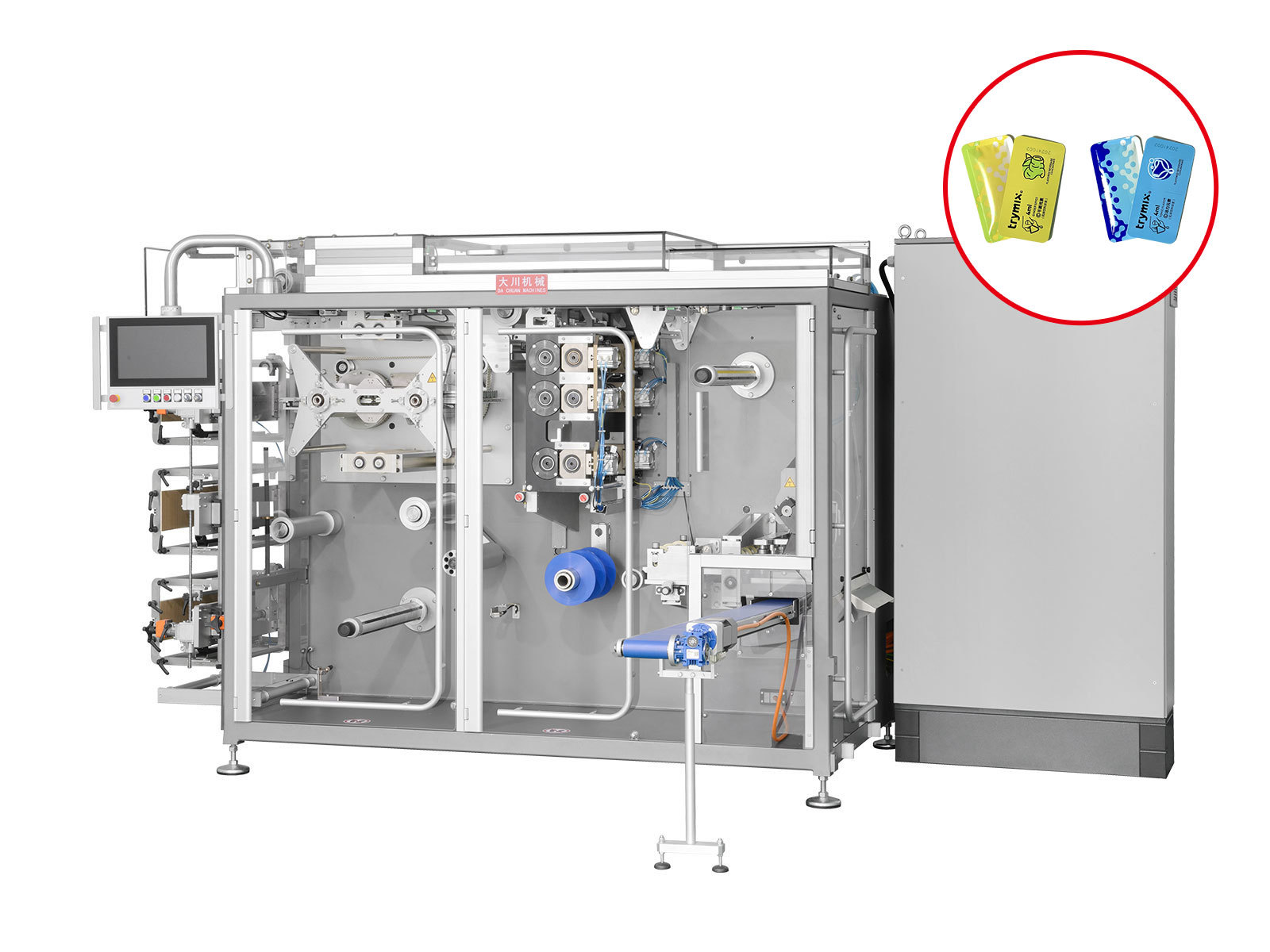

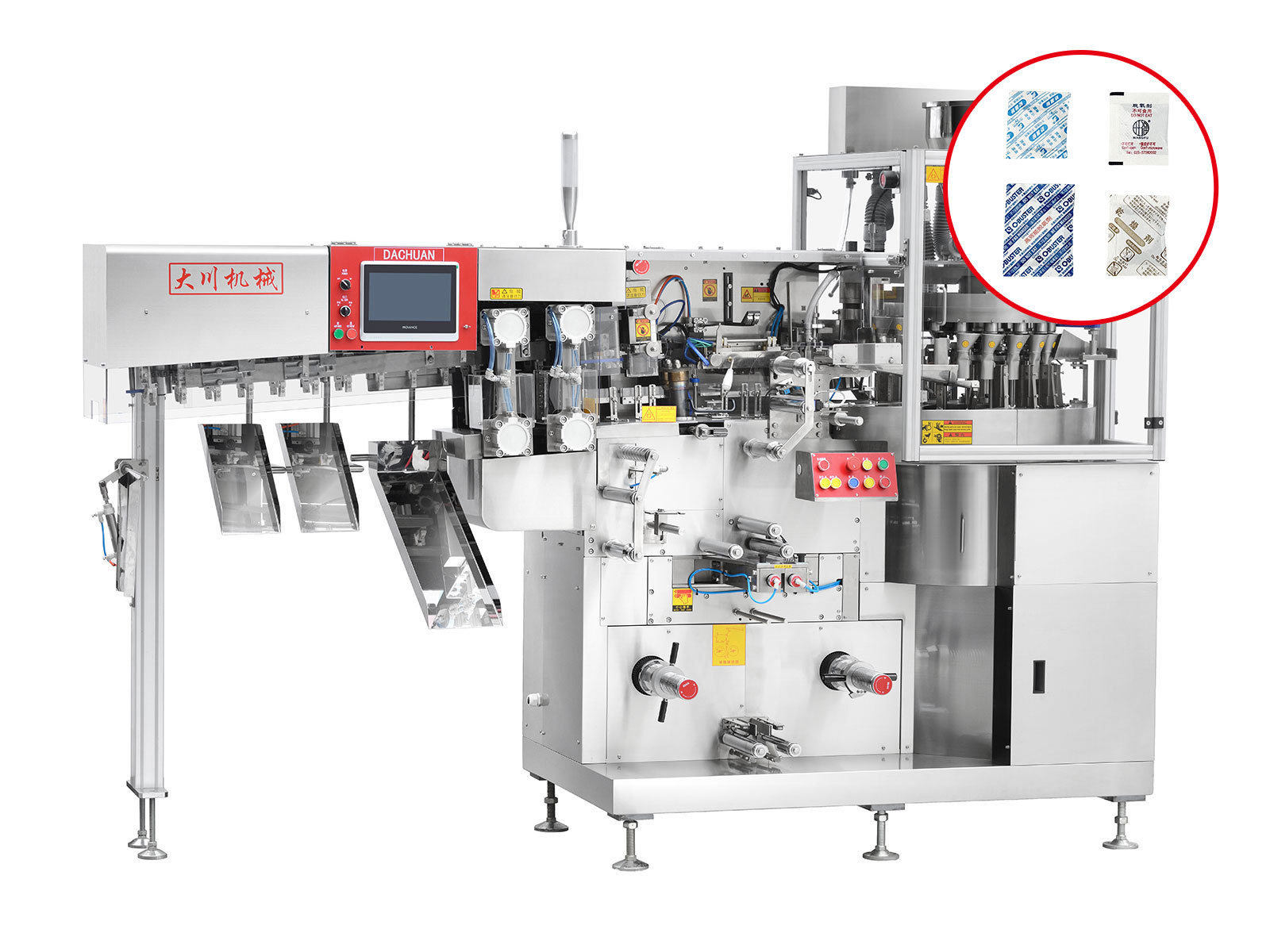

Product Center

Specializing in the manufacture of packaging machines

STRENGTH

Why choose us?

Dachuan Machines integrates scientific research, development, manufacturing, sales, and service. It has a batch of advanced processing centers, CNC lathes, precision engraving machines, grinding machines, double-sided milling machines, precision wire cutting machines, laser cutting machines, laser die-cutting machines, and shearing and pressing plate equipment, etc. All accessories are precisely inspected by quality inspectors. The mechanical manufacturing capacity is strong. Our company is market-oriented, constantly reforming and innovating, winning the trust and praise of related industries with high quality and excellent service. Employees have excellent business skills and have comprehensive capabilities in various aspects such as overall project design and development, manufacturing, installation and commissioning, technical training, and after-sales service. Advanced design concepts and professional technical advantages have always been the significant characteristics of Dachuan Machines. The complete processing system and rigorous after-sales service system have won a good reputation in the industry.

Service-oriented and deep cultivation of customer value

As a high-tech enterprise in Guangdong Province and the engineering technology research center for fully automatic high-speed high-performance intelligent packaging machines, the company has industry-leading R&D capabilities and can continuously launch high-performance intelligent packaging equipment to meet the market demand for efficient and precise packaging.

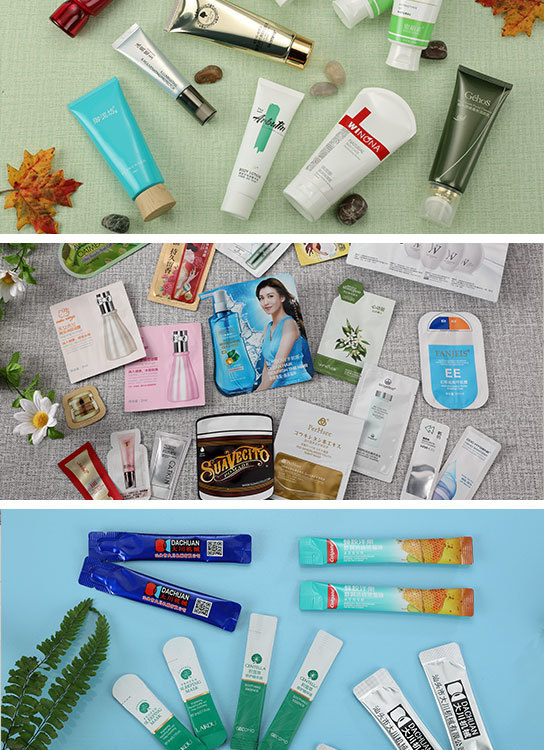

Complete product system and wide application

Products cover more than ten models such as pouch packaging machines, fully automatic tube sealing machines, and multi-row irregular machines, adapting to multiple fields such as food, daily chemicals, and medicine, and can handle various materials such as liquids, powders, and granules to meet the diversified needs of cross-industry customers.

Manufacturing strength and quality assurance

Equipped with advanced processing systems such as CNC lathes, laser cutting machines, and precision testing equipment, strictly implementing quality inspection procedures to ensure the accuracy of accessories and equipment stability. At the same time, it has comprehensive capabilities from design and development to after-sales service, ensuring efficient project implementation.

Service-oriented and deep cultivation of customer value

Adhering to the concept of "market-oriented, high-quality and excellent service", we have won industry reputation through a rigorous after-sales service system and rapid response mechanism. With the goal of "creating additional value for customers", we transform customer feedback into the driving force for technological upgrades and build long-term cooperative relationships.

QUALIFICATION CERTIFICATE

Qualification Certificate

Advanced design concepts and professional technical advantages have always been the significant characteristics of Dachuan Machines

SERVE CUSTOMERS

Serve Customers

Because of our professionalism, we are trustworthy. Your satisfaction is our persistent pursuit! Our progress comes from your continuous feedback!

SERVE CUSTOMERS

APPLICATION

Tailor-made industry solutions

News

Focus on real-time corporate dynamics, publish new authoritative information, and learn more

Regular operation precautions for automatic packaging machines

Before starting up, first check if the compressed air pressure meets the requirements (above 0.6bar), and check if all main components are intact, such as the heating belt, scissors, and various trolley parts. At the same time, check if there are other personnel around the machine to ensure safety after startup.

How to reduce air generated during packaging

We all know that vacuum packaging has greatly improved food packaging. Various packaging techniques are constantly emerging in the modern market, and the application of high technology has provided a solid foundation for the improvement of food packaging. Among many packaging techniques, each has its own advantages. The one I, the editor of Guangdong Lepai Intelligent Technology, am referring to here is a modified atmosphere packaging technique used in food packaging machines.

Instructions for Use of Food Pillow Packaging Machine

Factors concerning food pillow packaging machines include multiple aspects, such as: daily electricity use in objective factors. Food pillow packaging machines rely on connection to a power source to operate, and this daily electricity use often carries a relatively high risk. Operational safety and maintenance safety of the food pillow packaging machine itself belong to subjective factors. Therefore, the safety factor of food pillow packaging machines must be achieved through standardized operating procedures.

The trend towards smaller food packaging is obvious, and packaging machines still requires technological support.

High-precision measurement technology: Small packaged foods require higher measurement precision. Packaging machines needs to be equipped with high-precision metering devices, such as electronic scales, volumetric dispensers, etc., to ensure the accurate weight or volume of food in each small package. For example, in the production of small packaged foods like candies and nuts, measurement precision needs to be controlled within ±0.5 grams, which requires advanced measurement technology and sensors for precise measurement and control.

How should the food industry choose suitable packaging machines?

Different types of food require different types of packaging machines. For example, granular foods (such as nuts and candies) commonly use vertical or horizontal granular packaging machines; powdery foods (such as milk powder and flour) are suitable for using powder packaging machines, whose metering system can accurately control the filling amount of powder; liquid foods (such as beverages and soy sauce) require the use of liquid filling machines.

Common troubleshooting methods for food packaging machines

Food packaging machine refers to machinery capable of completing all or part of the product and food packaging process. The packaging process includes main operations such as filling, wrapping, and sealing, as well as related preceding and succeeding operations like cleaning, stacking, and disassembling. Additionally, packaging also includes operations such as weighing or imprinting on packaging units. Using machines for product packaging can improve productivity, reduce labor intensity, meet the needs of large-scale production, and satisfy hygiene requirements.